| AIR

QUALITY (FILTRATION & PURIFICATION)

Austin Air Systems - Information will be available soon

Ultraviolet

Air disinfection is the safe, easy and reliable way to

make it healthier indoors!

The solution for Microbial

Contaminants in HVAC systems. Dirty Socks Syndrome. Sick Building

Syndrome. These are some of the names given to mold and bacterial

problems in HVAC systems. Ultraviolet light is a very cost effective

method of destroying bacteria, viruses, yeasts, and molds. Ultraviolet

light will kill or inactivate these micro-organisms. The benefits

are many; increased HVAC coil efficiency, lower maintenance costs,

improved indoor air health, and it's very affordable.

For over 70 years, ultraviolet light has been an effective tool

in destroying harmful pathogens. Many of the molds, bacteria,

and fungi, that cause odours and problems in your air handling

system, can be eliminated with the installation of ultraviolet

light. It is used widely in industry to keep food and liquids

germ-free during processing and packaging. It's also used in aircraft

ventilation systems to prevent the spread of pathogens and infectious

disease.

Our UV air disinfection equipment 'floods' an area of a home or

buildings HVAC system with UV light. As it circulates throughout

the system, it is automatically disinfected. This simple process

dramatically reduces airborne bacteria, viruses and allergens.

|

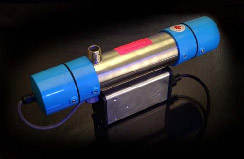

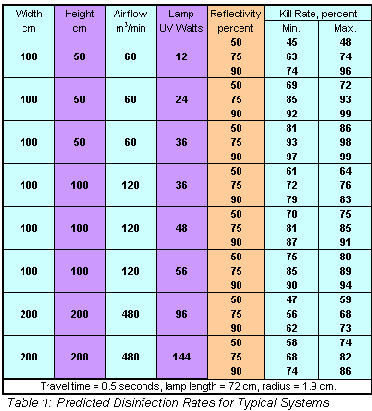

Shown

here is the UVInnovation UVIDII. Placed inside air duct.

Ideal for homes and businesses

|

Shown

here is the UV Innovation UVIP. ideal for apartments, boats,

cars, etc.

Shown

here is the UV Innovation UVIP. ideal for apartments, boats,

cars, etc. |

Features:

- Medical studies

prove the effectiveness of ultraviolet light.

- Available for residential,

commercial, industrial, and also portable applications.

- Eliminates or prevents

mold growth on HVAC coils, allowing them to operate at peak

efficiency.

- Actually destroys

bacteria, viruses, fungi, yeast, and molds.

- Inexpensive to

operate. Only pennies per day.

- High output, long

life UV lamps.

- Great for homes,

restaurants, offices, hospitals, schools, etc.

- Surface or airborne

microbial control.

- Low maintenance

and reduced costs.

The EPA says that indoor

air is one of the top five environmental health risks of our time.

And the Centre for Disease Control offers guidelines for using

UV to disinfect the air.

UV Air disinfection

systems work automatically -24/7

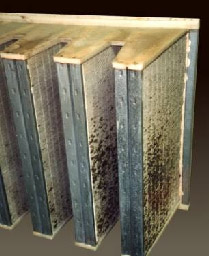

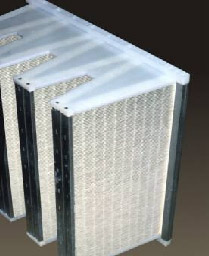

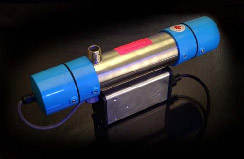

UVGI can control microbial

growth on filters subject to moisture or high humidity. Photos

A and B show an unirradiated and irradiated filter bank, respectively.

The unirradiated filters show natural contamination from various

fungal species, including Aspergillus and Penicillium, while the

irradiated filters show no evidence of microbial growth. The system

in Photo B used lamps that produce a rated intensity of 100 microW/cm2

at 1 m from their midpoints.

Microbial

growth on unirradiated filters |

Microbe-free

irradiated filters |

| Photos

courtesy of Airguard Industries, Louisville.

|

TYPES OF MICROORGANISMS

The variety of microbes encountered by a given UVGI system is

essentially unpredictable. It depends to some degree on the type

of facility and geographic location.

All viruses and almost all bacteria (excluding spores) are vulnerable

to moderate levels of UVGI exposure. Because viruses are primarily

contagious pathogens that come from human sources, they are found

in occupied buildings. Bacteria can be contagious or opportunistic,

with many found indoors; however, some are environmental. Certain

facilities, such as agricultural buildings, may disseminate unique

types of bacteria such as spore-forming actinomycetes.

Spores, which are larger and more resistant to UVGI than most

bacteria, can be controlled effectively through the use of high

efficiency filters. The coupling of filters with UVGI is the recommended

practice in all health care settings8 and for UVGI applications

in general.

DESIGN PARAMETERS

A number of parameters must be considered when considering UVGI

products for HVAC designs. The most important factors are the

airflow or HVAC equipment that will be disinfected, the lamp wattage

and distance, and the ventilation system design itself.

Air-stream characteristics

The characteristics

of an air-stream that can impact UVGI design are relative humidity

(RH), temperature, and air velocity.

Increased RH is commonly believed to decrease decay rates under

ultraviolet (UV) exposure. However, studies on this matter are

contradictory and incomplete at present. Fortunately, because

most UVGI studies were conducted under normal indoor conditions,

typical room and in-duct applications are not likely to differ

greatly. Air temperature has a negligible impact on microbial

susceptibility to UVGI10. However, it can impact the power output

of UVGI lamps if it exceeds design values.

Operating a UVGI

system at air velocities above design will degrade the system's

effectiveness because of the cooling effect of the air on the

lamp surface, which, in turn, will cool the plasma inside of the

lamp. UV output is a function of plasma temperature when power

input is constant.

Not all UVGI

lamps have the same response to cooling effects. Some lamps have

different plasma mixtures; overdriven power supplies that respond

to plasma temperature; or UV-transparent, infrared-blocking shielding

that limits cooling effects. Data from the manufacturer should

be consulted to determine the cooling effects or the limiting

design air velocities and temperatures within which the lamps

can be efficiently operated.

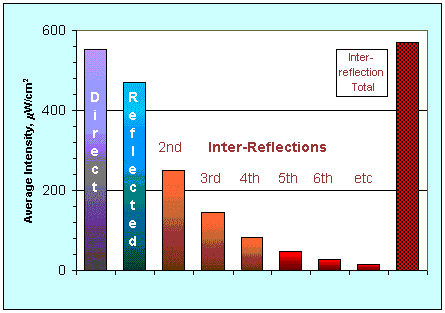

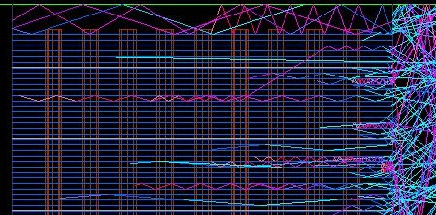

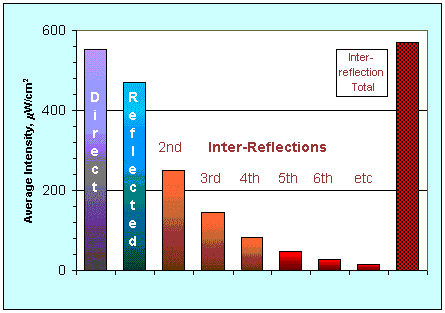

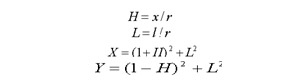

Figure

5: calculated additional light intensity from reflections and

inter-reflections. Total intensity is the sum of direct, reflected

and inter-reflected UV light.

VENTILATION SYSTEM DESIGN

A number of ventilation system parameters can impact UVGI design.

Air velocity and air mixing. Doses are determined by the time

of exposure and UVGI intensity, both of which are dependent on

the velocity profile and amount of air mixing in the air stream.

The velocity profile inside the duct or chamber depends on local

conditions and may be impossible to know in advance with any certainty.

In any event, the design velocity of a typical UVGI unit is similar

to that for filter banks -- about 400 fpm. Sufficient mixing will

occur at these velocities to temper the effects of a non-uniform

velocity profile.

The amount of air mixing that occurs will affect system performance

to a degree that depends on system configuration. This is illustrated

in Figure 4

which compares the survival predictions for mixed- and unmixed-flow

conditions in square ducts of increasing dimension. The error

resulting from the assumption of complete mixing will decrease

as system dimensions increase.

In systems where the lamps do not span the entire duct width or

length, the assumption of complete mixing also will result in

larger differences, compared to unmixed flow. The important point

is that system operation will lie somewhere between these two

assumptions, which provide limits describing system efficiency.

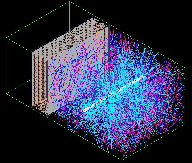

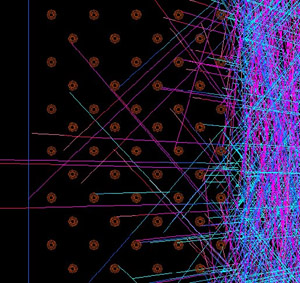

Figure

6. Ray-tracing computer model of a cooling coil bank irradiated

with a UVGI lamp. Rays are color-coded from blue to red in order

of decreasing intensity. Image was generated using Photopia software

from Lighting Technologies, Inc., Boulder, CO.

Using reflectors.

Reflectivity can be an economical way of intensifying the UVGI

field in an enclosed duct or chamber. A surface with a reflectivity

of 90 percent will reflect 9/10 of the light it receives.

The results of a computer-generated analysis of reflectivity are

shown in Figure 5. The components of reflectivity -- both direct

and inter-reflected -- will clearly sum to greater than the initial

direct intensity. This can occur whenever the surface is mostly

enclosed and highly reflective. Such designs can considerably

improve economics.

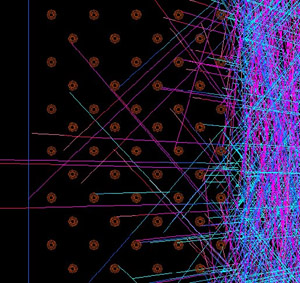

Figure

6b. Ray-tracing computer model of a cooling coil bank irradiated

with a UVGI lamp. Twenty reflections are shown with 90 percent

reflective surfaces. Image was generated using Photopia software

from Lighting Technologies, Inc., Boulder, CO.

Two types of reflective

surfaces exist: specular and diffuse. Specular surfaces produce

mirror-like reflections that are directionally dependent on the

source, while diffuse surfaces produce non-directional reflections

that spread equally in all directions. Non-glossy white paper

is a good example of a diffuse surface. Most materials possess

a combination of specular and diffuse properties and exhibit a

degree of directional dependence. For UVGI design purposes the

degree of directional dependence is usually not critical.

Some materials reflect visible light, but not UV light. Polished

aluminum is highly reflective to UV wavelengths, while copper,

which reflects most visible light, is transparent in the UV range.

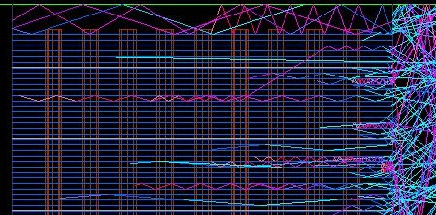

Figure 6c.

Ray-tracing computer model of a cooling coil bank irradiated with

a UVGI lamp. The staggered 5/4 coil tubes are 0.5 in. dia. with

six fins per inch. Image was generated using Photopia software

from Lighting Technologies, Inc., Boulder, CO.

No simple method of

calculating the three-dimensional UVGI-intensity field for specular

reflectors exists. Ray-tracing routines using Monte Carlo techniques,

are one approach, but the results do not easily lend themselves

to analysis. However, they can be rather useful for examining

complex geometries, such as when cooling coils are irradiated.

Figure 6 shows ray-tracing diagrams of a UVGI lamp irradiating

a bank of cooling coils from three perspectives. Note how few

of the rays penetrate the coils, even after 20 reflections. Also

note how the copper tubes absorb many of the rays -- although

(pure) copper is transparent to UVGI the water inside is not.

Combining with filtration

UVGI systems generally are used in combination with HEPA filters,

a practice usually recommended for isolation-room applications.

For other applications, however, HEPA filters do not offer a significant

enough improvement in microbial-removal rates over high efficiency

filters to warrant their exclusive use with UVGI.

Recirculation systems

UVGI systems that recirculate room air or that are placed in a

return-air duct or mixing-air plenum deliver multiple doses to

airborne microorganisms. Although the effect is partially dependent

on the air change rate, the result is an effective increase in

removal rate in comparison wit a single-pass system.

Calculations of removal rates for UVGI and associated filters

in recirculation systems can be performed by evaluating the system

minute-by-minute, including filtration rates, outside-air rates,

and any microbial contaminants.

Lamp considerations

The hardest part of sizing a UVGI system is determining the lamp

wattage for the stated disinfection goal. The intensity field

caused by the lamp and the reflectors must be modeled and averaged

before equation 1 is used to predict the disinfection rate.

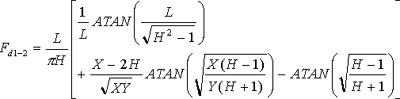

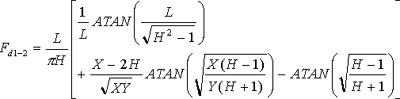

Calculating

the Intensity Field of a UVGI Lamp

The intensity field of a UVGI lamp can be computed using

the following radiation view factor from a differential

planar element to a cylinder, perpendicular to the cylinder

axis (Modest, M.F. 1993. Radiative Heat Transfer. McGraw-Hill,

New York):

The parameters in the above equation are defined as follows:

where l = length of the lamp segment, cm

x = distance from the lamp, cm

r = radius of the lamp, cm

The intensity at any point will be the product of the view

factor and the surface intensity of the lamp. The surface

intensity is simply the UV power output in watts divided

by the surface area in cm2.

To compute the intensity at any distance from the midpoint

of the lamp, multiply the above equation by 2. From any

location other than the midpoint, divide the lamp into two

unequal segments and add the two view factors. View-factor

algebra (see reference) can be used for other locations.

If we assume that complete mixing occurs, then the intensity

field for any duct can be computed by averaging the field

in all three dimensions. |

Lamp-intensity field

An exact description of the lamp-intensity field is necessary

to accurately determine the dose that is to be delivered to an

airborne microorganism. Lamp ratings often are the sole parameter

used for sizing a UVGI installation. Although this may be a conservative

approach when distances to the lamp exceed 1 meter, oversizing

and prohibitive economics can result.

If complete mixing is assumed, then any intensity field can be

described by the single value of average intensity. This requires

computing the intensity at every point in a three-dimensional

matrix defining the duct. We need to know the field caused by

the lamp and, if necessary, the field caused by the reflections.

Although the inverse-square law has been used for this purpose,

it has proven to be inaccurate close to the lamp. An improved

approach is to use the radiation view factor from a differential

planar element to a cylinder as detailed in the sidebar Calculating

the Intensity Field of a UVGI Lamp. Ignoring reflectivity, the

average intensity field can be conservatively computed by applying

Equation 3 to a three-dimensional matrix.

There are view factors that can be used for computing the reflected

intensity from flat parallel or perpendicular surfaces. Consult

any thermal-radiation textbook for such view factors. First, use

Equation 3 to determine the intensity at the flat surface. Then,

use the appropriate view factor to determine the reflected intensity

after multiplying by the reflectivity.

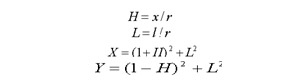

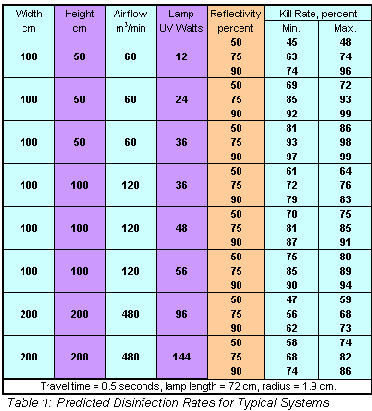

Table 1: presents a comparison of UVGI systems

that were sized using the view-factor method and may be used to

approximate the performance of similar systems.

CONCLUSIONS

Although

simplistic, the methodology presented here is more accurate than

any previously published method for sizing UVGI systems. The authors

hope that these principles will lead to successful applications

and avoidance of the design problems that have hampered the industry

and perplexed engineers. Although the goal of eliminating airborne

disease might remain unachievable, the information presented here

may help lead the industry back to the path of continuous improvement.

The use of ultraviolet

germicidal irradiation (UVGI) for the sterilization of microorganisms

has been studied since the 1930s. Microbes are uniquely vulnerable

to the effects of light at wavelengths at or near 2537 Angstroms

due to the resonance of this wavelength with molecular structures.

Looking at it another way, a quanta of energy of ultraviolet light

possesses just the right amount of energy to break organic molecular

bonds. This bond breakage translates into cellular or genetic

damage for microorganisms. The same damage occurs to humans, but

is limited to the skin and eyes.

The ultraviolet component of sunlight is the main reason microbes

die in the outdoor air. The die-off rate in the outdoors varies

from one pathogen to another, but can be anywhere from a few seconds

to a few minutes for a 90-99% kill of viruses or contagious bacteria.

Spores, and some environmental bacteria, tend to be resistant

and can survive much longer exposures. UVGI systems typically

use much more concentrated levels of ultraviolet energy than are

found in sunlight.

Some properly designed, and well-maintained, UVGI installations

have proven highly effective, as in certain hospitals, and some

studies perfomed in schools. CDC guidelines recommend the use

of UVGI only with the simultaneous use of HEPA filters and high

rates of purge airflow. The germicidal effects can also be species-dependent.

Laboratory tests have achieved extremely high rates of mortality

under idealized conditions. In actual applications, many factors

can alter the effectiveness of UVGI, including the following :

- Exposure time (the

air velocity must allow for a sufficient dose).

- Room air mixing

(for non-powered applications like ceiling units).

- Power levels.

- The presence of

moisture or particulates provide protection for microbes

- Dust settling on

light bulbs can reduce exposures, maintenance is necessary.

One

especially effective application of UVGI is the control of microbial

growth in air handling unit cooling coil and filter assemblies.

The constant exposure has been found to be very effective at

controlling fungal growth, either because the spores are inactivated,

or perhaps because mycelial growth cannot be sustained under

continuous exposure.

Certain types of UVGI designs seem to provide a much higher

rate of disinfection than standard models operating at nearly

identical spectrums, the difference being the result of improvements

in the electrical power controls and regulation of internal

plasma temperature, resulting in the generation of a more constant

energy density at a distance from the light source.

Viruses are especially susceptible to UVGI, more so than bacteria,

but are also very difficult to filter. Some studies have shown

that viruses are more sensitive to ultraviolet radiation at

wavelengths somewhat above the normal UVGI broad-band wavelength

of 2537 A (Rauth 1965; Setlow 1961). A combination of filtration

for bacteria and spores, with UVGI for viruses may be an optimum

combination if all components are sized appropriately.

UVGI THEORY & RATE CONSTANTS FOR AIRBORNE PATHOGENS

UVGI inactivates pathogens according to the standard decay equation

S = exp(-kIt)

In this

equation S represents the fraction of the original population

that survives exposure at time t, and I represents the UVGI

intensity. The rate constant k has been determined experimentally

for a number of bacteria, viruses and spores, at different power

levels. Summarized below are many of the known rate constants

for the indicated pathogens. Since many researchers have obtained

values that differ, they have all been included. The source

documents may be found in the references.

|